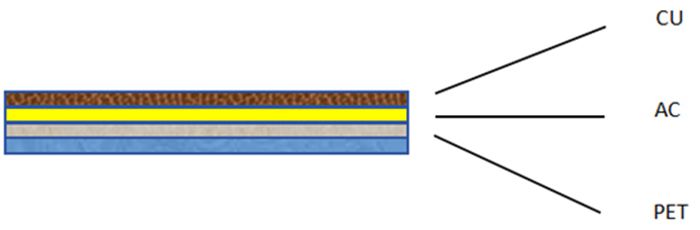

- Total Thickness: (From 10μm to over 100μm) ±3μm

- PET Layer Thickness: (≥1.6μm) + Copper Layer (≥4μm)

- Tensile Strength: ≥30Mpa

- Width: 0.5mm to 990mm

- Elongation: ≥30% Min

- Packaging: rolls(D30), sheets, 76mm removable rolls, converted cone packaging

Copper foil offers conductivity and electromagnetic insulation. PET film provides electrical insulation and high mechanical strength. Copper foil is corrosion-resistant, radiation-resistant, weldable, and offers higher conductivity than aluminum foil. We also offer adhesive-free foil film laminates tailored to your needs.

- PET film protects copper foil from damage and oxidation

- Copper foil provides electrical shielding, while PET film offers insulation

- EMI shielding

- Data transmission cable

RA copper foil and ED copper foil have their respective advantages and disadvantages.

- RA copper foil is purer in terms of copper content.

- RA copper foil offers better overall physical performance compared to electrolytic copper foil.

- Both types of copper foil have nearly identical chemical properties.

- In terms of cost, ED copper foil is usually less expensive due to its simpler manufacturing process and the ease of mass production.

- Typically, RA copper foil is used in the early stages of product manufacturing, but as manufacturing processes mature, ED copper foil is often utilized to reduce costs.

Polyester Film Tape (PET Tape)

Polyester Film Tape (PET Tape) Shielding Laminates

Shielding Laminates Vacuum Metallized Films & Fabrics

Vacuum Metallized Films & Fabrics